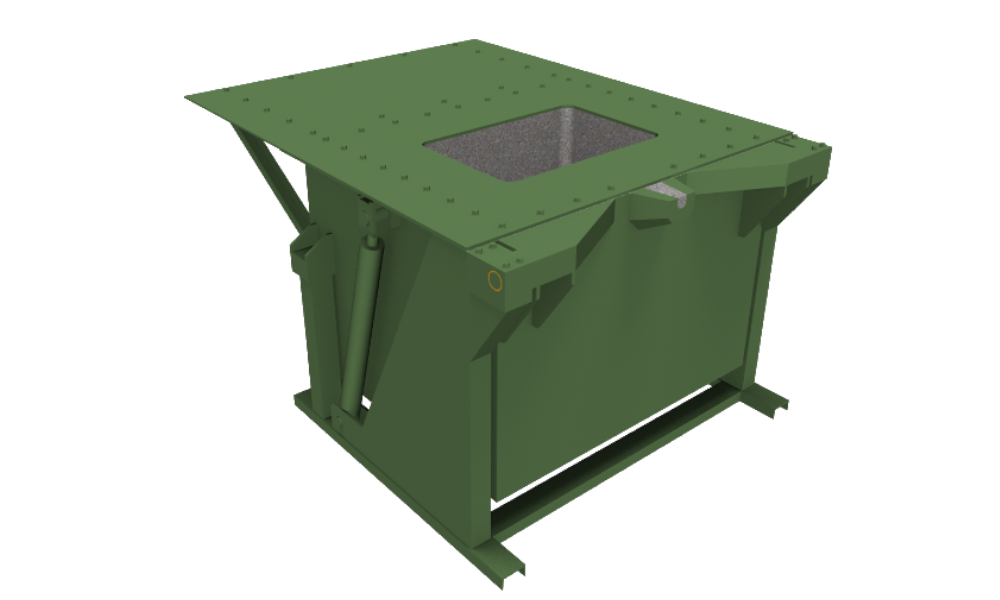

OVENS FOR ALUMINUM MELTING

OVENS TYPE T.O.S.C.AL.

Three phase low frequency induction oven two basins suitable for fusion and melting alluminium alloy. This type of oven to the new conception is suitable for use in die casting (cold room) and gravity fusion, with the extraction of the manual or automatic molten metal.

- Electric with a good yield ratio indicated to 1,8 Kg. the 1 KW

- Decrease of less than traditional metal smelters and elimination of normal (foams)

- Metal temperature constant and uniform

- High quality cast metal with the almost total elimination of hard points

- Good durability of refractory and the elimination of the crucibles

| OVEN TYPE | CAPACITY | NOMINAL POWER MAX. | PRODUCTION/h IND. MAX | ||||||

|---|---|---|---|---|---|---|---|---|---|

| T.O.S.C./ 6 | Kg. 600 | K.V.A. 80 – KW. 76 | 205 Kg./h | ||||||

| T.O.S.C./ 9 | Kg. 900 | K.V.A. 120 – KW. 115 | 310 Kg./h | ||||||

| T.O.S.C./ 14 | Kg. 1400 | K.V.A. 150 – KW. 140 | 380 Kg./h | ||||||

OVENS TYPE T.M.ALL./R.

Three phase low frequency induction oven. Suitable for melting and scrap of aluminum for the production of ingots, billets and the power of holding furnaces.

| OVEN TYPE | CAPACITY | NOMINAL POWER MAX. | PRODUCTION/h IND. MAX | ||||||

|---|---|---|---|---|---|---|---|---|---|

| T.M.ALL./R. 150 | Kg. 1000 | K.V.A. 150 – KW. 140 | 250 Kg./h | ||||||

| T.M.ALL./R. 300 | Kg. 1500 | K.V.A. 300 – KW. 285 | 550 Kg./h | ||||||

| T.M.ALL./R. 450 | Kg. 2000 | K.V.A. 400 – KW. 380 | 700 Kg./h | ||||||